Embark on a journey into the realm of electrical engineering as we delve into the intricacies of NEC Chapter 9 Table 8 conductor properties. These conductors play a pivotal role in the safe and efficient transmission of electrical power, and understanding their characteristics is paramount for electrical professionals.

In this comprehensive guide, we will explore the electrical conductivity, ampacity ratings, resistance, reactance, insulation types, and applications of NEC Chapter 9 Table 8 conductors. By delving into these concepts, we will gain invaluable insights into the selection and utilization of conductors in various electrical systems.

Electrical Conductivity: Nec Chapter 9 Table 8 Conductor Properties

Electrical conductivity is a measure of a material’s ability to conduct electricity. In NEC Chapter 9 Table 8, the electrical conductivity of conductors is specified for various materials, such as copper, aluminum, and steel.

The electrical conductivity of a material is influenced by several factors, including its composition and temperature. Generally, metals have higher electrical conductivity than non-metals. The conductivity of a material also decreases with increasing temperature.

Examples of high conductivity conductors include copper and silver, while examples of low conductivity conductors include iron and steel.

Ampacity Ratings

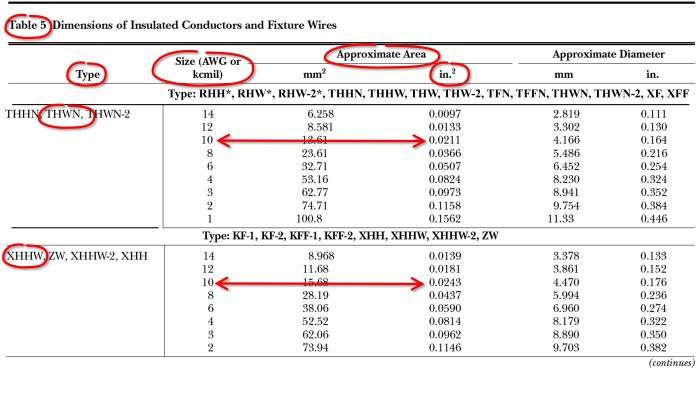

Ampacity refers to the maximum amount of current that a conductor can safely carry without overheating. The ampacity ratings provided in NEC Chapter 9 Table 8 are based on factors such as the conductor size, material, insulation type, and ambient temperature.

The ampacity rating of a conductor is important because it helps ensure the safety and reliability of electrical systems. If a conductor is overloaded, it can overheat and cause a fire or other electrical hazards.

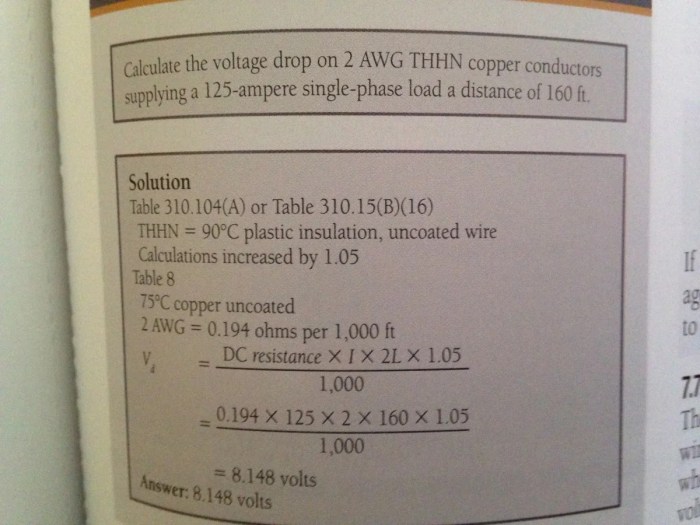

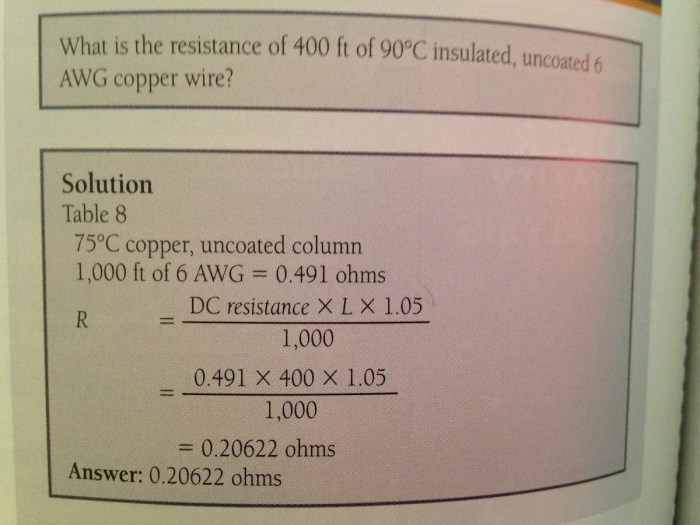

Resistance and Reactance

Resistance is a measure of the opposition to the flow of electric current through a conductor. Reactance is a measure of the opposition to the flow of alternating current (AC) through a conductor.

Resistance and reactance affect the performance of conductors in AC circuits. Resistance causes a voltage drop across the conductor, while reactance causes a phase shift between the voltage and current.

The resistance of a conductor can be calculated using the following formula:

R = ρL/A

Where:

- R is the resistance in ohms

- ρ is the resistivity of the conductor material in ohm-meters

- L is the length of the conductor in meters

- A is the cross-sectional area of the conductor in square meters

The reactance of a conductor can be calculated using the following formula:

X = 2πfL

Where:

- X is the reactance in ohms

- f is the frequency of the AC current in hertz

- L is the length of the conductor in meters

Insulation Types

NEC Chapter 9 Table 8 lists various types of insulation used in conductors. The type of insulation affects the conductor’s performance and safety.

Common types of insulation include:

- Thermoplastic (THHN): This type of insulation is made from a thermoplastic material, such as PVC or nylon. It is flexible and resistant to heat and moisture.

- Cross-linked polyethylene (XLPE): This type of insulation is made from a cross-linked polyethylene material. It is more durable and heat-resistant than THHN insulation.

- Ethylene propylene rubber (EPR): This type of insulation is made from an ethylene propylene rubber material. It is flexible and resistant to heat and moisture.

- Polyvinyl chloride (PVC): This type of insulation is made from a polyvinyl chloride material. It is inexpensive and easy to install, but it is not as durable as other types of insulation.

Conductor Applications

NEC Chapter 9 Table 8 conductors are used in a variety of applications, including:

- Residential wiring: These conductors are used to distribute electricity throughout homes and apartments.

- Commercial wiring: These conductors are used to distribute electricity throughout commercial buildings, such as offices and stores.

- Industrial wiring: These conductors are used to distribute electricity throughout industrial facilities, such as factories and warehouses.

When selecting conductors for a specific application, it is important to consider factors such as the voltage, current, and temperature requirements of the application.

FAQs

What is the significance of electrical conductivity in NEC Chapter 9 Table 8 conductors?

Electrical conductivity determines the ability of a conductor to carry electrical current. High conductivity conductors minimize energy losses due to resistance, making them suitable for long-distance power transmission.

How do ampacity ratings impact conductor selection?

Ampacity ratings specify the maximum current a conductor can safely carry without overheating. Selecting conductors with appropriate ampacity ratings ensures the safe operation of electrical circuits.

What is the role of insulation in NEC Chapter 9 Table 8 conductors?

Insulation prevents electrical current from leaking out of the conductor, ensuring safety and preventing short circuits. Different insulation types offer varying levels of protection and are suitable for specific applications.