Embark on a fascinating journey into the realm of separating mixtures, where we uncover the secrets of separating a mixture lab answers. From filtration to distillation, we delve into the intricacies of each technique, exploring their principles, applications, and limitations.

Get ready to unravel the mysteries of matter and master the art of separating mixtures with confidence!

This comprehensive guide will equip you with a thorough understanding of the methods used to separate mixtures, empowering you to tackle any separation challenge with ease. Whether you’re a student seeking to excel in your lab experiments or a professional seeking to enhance your knowledge, this guide is your ultimate resource.

Methods of Separating Mixtures

Mixtures can be separated into their individual components using various methods, depending on the physical and chemical properties of the components. One common method is filtration, which is used to separate solids from liquids or gases.

Filtration

Filtration is a mechanical process that involves passing a mixture through a filter, which is a porous material that allows the liquid or gas to pass through while trapping the solid particles. The filter paper used in filtration is made of cellulose, a natural polymer that has a network of tiny pores.

The size of the pores determines the size of the particles that can be trapped by the filter paper.Filtration is commonly used to separate mixtures such as:

- Sand and water

- Coffee grounds and coffee

- Dust and air

Decantation

Decantation is a simple method used to separate immiscible liquids or a solid from a liquid. Immiscible liquids are those that do not mix together, such as oil and water. In decantation, the mixture is allowed to settle, and the heavier liquid or solid settles at the bottom of the container.

The clear liquid is then carefully poured off, leaving the heavier liquid or solid behind.

Examples of Mixtures Separated by Decantation

Decantation can be used to separate a variety of mixtures, including:

- Oil and water

- Sand and water

- Gravel and water

- Iron filings and water

Limitations of Decantation

Decantation is not effective for separating mixtures where the components have similar densities. For example, it is not possible to separate a mixture of alcohol and water using decantation because the two liquids have very similar densities. Additionally, decantation can be time-consuming, especially for large volumes of liquid.

Centrifugation

Centrifugation is a technique used to separate mixtures based on the differences in their densities. It involves spinning a mixture at high speed, causing denser particles to move to the outside of the container while less dense particles remain in the center.

Types of Centrifuges

There are two main types of centrifuges:

- Preparative centrifugesare used to separate large volumes of mixtures. They can generate high centrifugal forces, allowing for the separation of particles with small density differences.

- Analytical centrifugesare used to study the properties of particles in a mixture. They generate lower centrifugal forces and are used to determine the size, shape, and density of particles.

Applications of Centrifugation

Centrifugation is used to separate a wide variety of mixtures, including:

- Blood: Centrifugation can be used to separate blood into its components, such as red blood cells, white blood cells, and plasma.

- Milk: Centrifugation can be used to separate milk into cream and skim milk.

- Oil and water: Centrifugation can be used to separate oil and water, which have different densities.

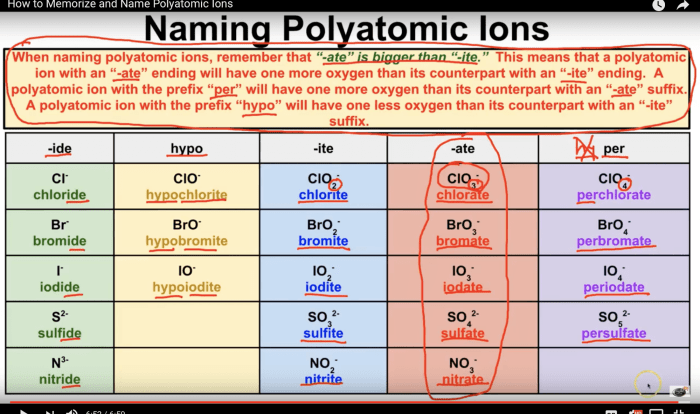

Chromatography

Chromatography is a separation technique used to separate components of a mixture based on their different physical and chemical properties. It involves passing a mixture through a stationary phase, which is a solid or liquid, while a mobile phase, which is a liquid or gas, moves through the stationary phase.

The components of the mixture interact with the stationary and mobile phases differently, causing them to separate.There are several different types of chromatography, including:

Paper Chromatography

In paper chromatography, the stationary phase is a sheet of paper, and the mobile phase is a solvent. The mixture is applied to the paper, and the solvent is allowed to move through the paper by capillary action. The components of the mixture separate based on their different affinities for the paper and the solvent.

Thin-Layer Chromatography

Thin-layer chromatography is similar to paper chromatography, but the stationary phase is a thin layer of adsorbent material, such as silica gel or alumina, on a glass or plastic plate. The mobile phase is a solvent or mixture of solvents.

Thin-layer chromatography is often used to separate small amounts of compounds.

Gas Chromatography

Gas chromatography is used to separate volatile compounds. The stationary phase is a solid or liquid coated on the inside of a glass column. The mobile phase is a carrier gas, such as helium or nitrogen. The mixture is injected into the column, and the components of the mixture separate based on their different boiling points.

Liquid Chromatography

Liquid chromatography is used to separate non-volatile compounds. The stationary phase is a solid or liquid coated on the inside of a column. The mobile phase is a liquid or mixture of liquids. The mixture is injected into the column, and the components of the mixture separate based on their different affinities for the stationary and mobile phases.Chromatography

is a powerful technique that can be used to separate a wide variety of mixtures. It is used in many different fields, including chemistry, biology, and medicine.

Distillation

Distillation is a separation technique that uses heat to separate a liquid mixture based on the different boiling points of its components. The mixture is heated to a temperature at which the more volatile component vaporizes, leaving behind the less volatile component.

The vapor is then condensed back into a liquid, and the two components are collected separately.There are two main types of distillation: simple distillation and fractional distillation. Simple distillation is used to separate liquids with a large difference in boiling points, while fractional distillation is used to separate liquids with similar boiling points.Examples

of mixtures that can be separated using distillation include:

- Water and salt

- Alcohol and water

- Gasoline and kerosene

Sublimation

Sublimation is a physical process in which a solid substance directly transforms into a gas state without passing through the liquid phase. This phenomenon occurs when the temperature and pressure conditions allow the solid to bypass the liquid phase and transition directly into a gas.

Sublimation is a useful technique for separating mixtures containing solid and gaseous components. By heating the mixture to a temperature where the solid sublimates, the gaseous component can be collected and separated from the remaining solid.

Examples of Mixtures Separated by Sublimation

- Camphor from sawdust

- Iodine from sand

- Dry ice (solid carbon dioxide) from water

Advantages of Sublimation

- Efficient separation of solid-gas mixtures

- No need for solvents or other liquids

- Can be used to purify solids

Disadvantages of Sublimation

- Requires specialized equipment (e.g., sublimation apparatus)

- Not suitable for all solid-gas mixtures

- Can be time-consuming

Magnetic Separation

Magnetic separation is a technique used to separate magnetic materials from non-magnetic materials. It is based on the principle that magnetic materials are attracted to magnets, while non-magnetic materials are not.

There are different types of magnetic separators, including:

- Drum separators:These separators consist of a rotating drum covered with a magnetic material. As the drum rotates, the magnetic material attracts and holds the magnetic particles in the mixture. The non-magnetic particles are then removed by a scraper.

- Belt separators:These separators consist of a conveyor belt covered with a magnetic material. As the belt moves, the magnetic material attracts and holds the magnetic particles in the mixture. The non-magnetic particles are then removed by a scraper.

- Cross-belt separators:These separators consist of a conveyor belt that passes over a magnetic field. As the belt moves, the magnetic material attracts and holds the magnetic particles in the mixture. The non-magnetic particles are then removed by a scraper.

Magnetic separation can be used to separate a variety of mixtures, including:

- Iron ore from sand

- Steel from aluminum

- Nickel from copper

Electrostatic Separation

Electrostatic separation is a technique used to separate particles based on their electrical properties. It is commonly employed in various industries, including mining, recycling, and food processing, to separate materials with different electrostatic charges.

The principle behind electrostatic separation lies in the ability of particles to acquire an electrical charge when they come into contact with each other or with an external source. The acquired charge can be either positive or negative, depending on the material’s properties and the nature of the contact.

Types of Electrostatic Separators

There are several types of electrostatic separators, each designed to handle specific materials and applications. Some of the most common types include:

- Corona discharge separators: These separators use a high-voltage electrode to generate a corona discharge, which ionizes the air and charges the particles in the mixture.

- Triboelectric separators: These separators rely on the triboelectric effect, where particles acquire opposite charges when they come into contact with each other. The charged particles are then separated using an electric field.

- Electrostatic precipitators: These separators are used to remove particulate matter from gases. They use a high-voltage electric field to charge the particles, which are then collected on a grounded electrode.

Applications of Electrostatic Separation

Electrostatic separation has a wide range of applications, including:

- Mineral processing: Separating minerals based on their electrical properties, such as separating copper from gold or diamonds from kimberlite.

- Recycling: Separating different types of plastics, metals, and paper based on their electrical charges.

- Food processing: Removing unwanted materials, such as stones, dirt, and insects, from grains and other food products.

- Air pollution control: Removing particulate matter from industrial emissions.

Flotation

Flotation is a method of separating a mixture by selectively causing one or more components to float on the surface of a liquid.

The principle behind flotation is that different components of a mixture have different densities and surface tensions. When the mixture is placed in a liquid, the components with the lower density will float on the surface, while the components with the higher density will sink.

Types of Flotation Processes

There are two main types of flotation processes: froth flotation and solvent extraction.

- Froth flotationis used to separate hydrophobic (water-repelling) components from hydrophilic (water-loving) components. In this process, a frothing agent is added to the mixture, which causes bubbles to form. The hydrophobic components will attach themselves to the bubbles and float to the surface, while the hydrophilic components will remain in the liquid.

- Solvent extractionis used to separate components that are soluble in different solvents. In this process, a solvent is added to the mixture, which dissolves one or more of the components. The dissolved components will then be separated from the undissolved components using a separation funnel.

Examples of Mixtures that can be Separated Using Flotation

Flotation can be used to separate a variety of mixtures, including:

- Minerals from ores

- Oil from water

- Plastics from paper

Solvent Extraction: Separating A Mixture Lab Answers

Solvent extraction is a separation technique that uses a solvent to selectively dissolve one or more components of a mixture, leaving the other components behind. The solvent is chosen based on its ability to dissolve the desired component(s) while being immiscible with the other components.

There are two main types of solvent extraction processes: liquid-liquid extraction and solid-liquid extraction.

Liquid-Liquid Extraction, Separating a mixture lab answers

Liquid-liquid extraction is used to separate two immiscible liquids. The mixture is placed in a separating funnel, and the two liquids are allowed to separate. The upper layer is then carefully removed using a pipette or syringe.

Solid-Liquid Extraction

Solid-liquid extraction is used to separate a solid from a liquid. The mixture is placed in a Soxhlet extractor, and the solvent is heated to reflux. The solvent dissolves the solid, and the solution is then condensed and collected.

Solvent extraction is a versatile technique that can be used to separate a wide variety of mixtures. Some examples of mixtures that can be separated using solvent extraction include:

- Oil and water

- Caffeine and coffee

- Essential oils and plant material

- Drugs and biological fluids

Answers to Common Questions

What is the most common method for separating a mixture?

Filtration is the most commonly used method for separating a mixture, as it is simple, effective, and can be used to separate solids from liquids or gases.

What is the difference between decantation and centrifugation?

Decantation is a method used to separate liquids with different densities, while centrifugation is a method used to separate solids from liquids or gases by spinning the mixture at high speed.

What is the principle behind chromatography?

Chromatography is a separation technique that separates components of a mixture based on their different rates of movement through a stationary phase.